Recommended Practices to Store, Handle & Transport Cooking Oils

From the very mention of the term vegetable oil or cooking oil, all we think about is preparing food. From our simple homes to leading cafés and restaurants cannot imagine starting off their day without a bottle of cooking oil, because, without it, almost nothing is possible. But the truth is, even though vegetable oil such as olive oil, soybean oil, sunflower oil , peanut oil is used majorly as cooking oil; it has a variety of uses that are beyond the four walls of a kitchen. It is a key element in industrial production as it is an additive in fuels as well as in the making of pet food. Maybe a lot of you reading this article did not know that cooking oil is used for more than just cooking, but what’s more, to find out in this article is the care taken by major industry players while storing and transporting this cooking oil.

This article will shower light on some key elements with regards to the storage and transport of cooking oil, but to put it in perspective, this article will help you understand:

• The need for a good quality transport system

• Types of deterioration risks to be considered

– Oxidation

– Hydrolysis

– Contamination

• Designs for storage and transport

– Land Storage tankers

– Ship Tankers

– Rail and Road Tanks

• Elements to focus on for efficient storage

– Heating

– Cleaning

– Maintenance

What is the need for a good quality transport system?

To begin with, it is important to understand the need for a good quality transport system. There are many different types of vegetable oils and as much as it is required for cooking, it is an essential element in the production of other by-products as well. Hence there are two main reasons why there needs to be a quality transport service to deliver oil from one industry to another.

• Focus on flexibility: Since cooking oil has many varied uses, it needs to be delivered on time to produce various other products. This is one of the major reasons why when cooking oil is transported; it is transported in bulk almost at all times. Implementing a good quality transport service will help avoid any glitch related to delayed delivery, as this will even lead to spoilage of the commodity unless precise steps are taken.

• Reduce the chances of delayed delivery: A delayed delivery will not only result in the spoilage of the commodity, but it will result in a chain of unfortunate events. Think of the delay as a reason to set off an economic disaster, where vegetable-cooking oil is not available to you at your fingertips. As important it is to deliver cooking oil for further production, it is also important to deliver it on time to reach end users on time. Being a vital ingredient in cooking, a restaurant establishment could run losses if there is a shortage of cooking oil. If you are thinking from an industrial point of view then a simple delay could result in a halt in the production of your favorite items such as soaps and cosmetics among other by-products.

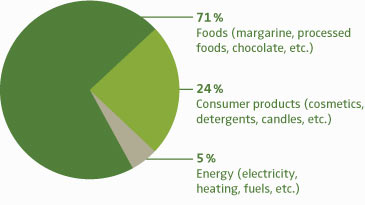

These pointers depict how important it is to not only have a good quality transport system to deliver vegetable oil from one destination to another but also gives you an insight into how significant this oil is in maintaining a steady flow of the economy. The reason I mentioned the “steady flow of the economy” is because one-third of the business activities of industries within the production vertical involve transporting cooking oil from one place to another. The below chart depicts the usage of simple vegetable-cooking oil in the production industry.

This chart clearly shows the necessity of cooking oil, therefore now it is evident as to why there is a need for a quality transport service. So ultimately the next question is what are the right practices to follow for storing and transporting cooking oil.

What are the types of deterioration risks to be considered?

There are three types of deterioration risks that need to be taken into account while storing and transporting cooking oil. This risk depends on the type of oil or fat that is being stored. If not taken care, these risk factors could result in loss of the oil for the company as well as its clients.

• Oxidation: This is the risk that arises from the contact of the oil with the oxygen in the atmosphere. This may seem like a tiny problem while reading the article, but the impact of oxidation can lead to major problems. Oxidation causes chemical abnormalities in the commodity and thereby downgrades the quality of the oil produced. Although in certain cases some effects of oxidation can be rectified with extra processing, it runs heavy expenses for the company.

• Hydrolysis: In science class, we did learn the importance of storing oil in a very clean tank, but the reason was never told to us. Well if there are small microorganisms or the presence of water molecules in the tank it leads to hydrolysis. It breaks down the fats in oil to fatty acids and renders the oil useless for further production as well as basic cooking. Therefore care must be taken while drying the tank, which will be used for storage of the cooking oil.

• Contamination: If there are any remaining residues of the previously stored products or presence of any other element such as dirt is present in the tank, adding the oil for storage to this tank will lead to contamination. It may prove to be a hassle to ensure the complete cleanliness of pipelines and valves, but contamination can be overcome by installing an efficient system with adequate cleaning procedures and inspections.

These three risk factors must be kept in mind before designing storage and transportation plan, as these risk factors are difficult to rectify. Understanding these risk factors is a start to the process. Now we will develop on this understanding by looking into the types of storage and transportation techniques that are available.

What are the designs for storage and transport that can be adopted?

There are so many varieties of designs that can be adopted in order to be able to store and transport oil efficiently. Though the main type of container used to store vegetable-cooking oil is a tank, there are different types of tanks that can be used. Through this article, we will look at some of the most efficient models that will help you create an effective storage and transport system.

Land Storage Tanks:

The most commonly seen, vertical, circular cross-section tank that comes with a self-supporting roof that is slightly convex in shape is by far the best oil storage tank available in the industry.

These are the tanks that we commonly see and this is very effective in storing oil while minimizing the contact with dirt, oxygen as well as water, thereby reducing the risk of deterioration. These tanks need to have a sloped bottom in order to facilitate effective draining of the tank.

As a recommendation, if the tank is used to store oil that will be made available for end users, consider the use of small size storage tanks with a relatively low capacity. The reason for this recommendation lies in three key criteria to be followed while choosing a storage tank:

• Anticipated storage period

• Turnover rate

• Number of products to be handled

Taking these points into consideration, if you are producing cooking oil for the end user and not for further production, then maintaining small size tanks are better as the storage periods will be short and you will not be handling any other by-products.

Ship Tanks:

In order to be able to cater to the “bulk transport of oil” requirement, ship tanks have proven to be extremely efficient. With capacities varying from 200 to 2500 tonnes, a single vessel carries these tanks or cargoes from one place to another. Made out of mild steel, these tanks are coated to avoid corrosion and additionally needs to be approved for contact with cooking oil that is ultimately used to make food.

These tanks require heavy inspection in order to ensure that the coating is still in place, but with the move to stainless steel, the use of the coating is reducing. Ship tanks are often categorized into three types:

• Bulk tankers: With a capacity of over 15000 to 40000 tonnes, these usually include inter-connected pipelines and most commonly used for the storage and transport of single oils.

• Parcel tankers: With a similar capacity range as the bulk tankers, these are more sophisticated and are designed to effectively carry different types of oils.

• Container vessel: A vessel that is designed to carry tanks of standardized dimensions which enhances the convenience in storage and transport.

Rail and Road Tanks:

These are tanks equipped to transport oil by and from one place to another. Most commonly used material for this tank is stainless steel or mild steel and if you are into production of end-user oils then this tanker will be perfect.

Similar to the others, this tank also helps in reducing the chances of deterioration if taken care of appropriately. The coating on this tank is also very essential to be well maintained as it can contaminate the oil stored inside.

What other elements must be focused for efficient storage?

What needs to be focused on during the implementation of an efficient storage system are as follows:

• Heating: it is essential to install appropriate heating facilities in the tanks in order to maintain the viscosity of the oils, that is the liquid and homogenous structure of the oil, during loading, transport, and unloading. Care must be taken to ensure that the heating coils are made of stainless steel and nor alloys consisting of copper as they could run risks of contaminating the commodity.

• Cleaning: As mentioned before, the cleanliness of the storage tank is very essential if you want to maintain the oil quality. It must be ensured that edible and non-edible oils are not mixed, as if not cleaned properly, they could prove to be hazardous for health. Regular inspections must be incorporated to ensure the cleanliness of the tanker. For instance, if water or steam is used to clean the tank it must be drained completely before storing the oil as it could lead to hydrolysis. Similarly, if any time of alkali is used to clean the pipelines and valves, they need to be washed out thoroughly to eradicate any remaining residues.

• Maintenance: A well-structured maintenance process needs to be incorporated along with the cleanliness inspection. This maintenance check should involve the check of steam pressure valves, steam supply pipelines, steam traps, weighing equipment, tank coatings, and gauge meters. These checks will help you measure the efficiency of their functioning and facilitate an overall check on the storage tank.

Storage and transport of cooking oil are very essential to ensure that there is a steady supply of the commodity across industries. Industries place ultimate importance on maintaining the quality of the storage and transport tank, as it is very essential as an industry standard. Many times oil gets rejected due to its incapability to meet the industry quality standards. Therefore key focus needs to be placed on the type of storage tanker you are choosing and the types of risk factors that you need to avoid in order to maintain the quality. Oil is like liquid treasure and especially in the case of vegetable-cooking oil, this holds true. With many varied uses and production of by-products, an efficient transport and storage system needs to be maintained.

Disclaimer – “Views expressed in the blogs, are exclusive thoughts of the author and are not necessarily

aligned to Vilina Refined Oil’s policies”.